In this year-long project, we attempted to determine whether the Formlabs Form 2 3D printer could be used to produce ceramic pressure housings for underwater applications. The project members were myself, Kelsey Dugan, and Mike Robinson (all URI Class of 2020), advised by Professor Brennan Phillips. The report abstract is posted below.

Skills developed: Ceramics, Manufacturing processes, SolidWorks, PreForm, 3D printing, SLA 3D printing, Experiment design, Data analysis, Pressure housings

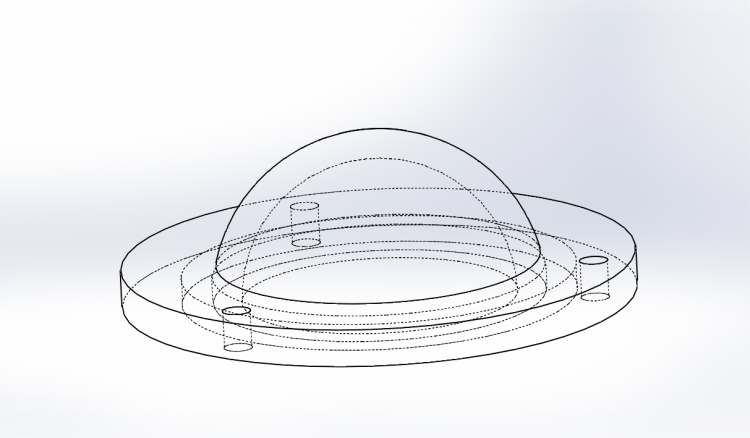

A SolidWorks model of one half of a spherical pressure housing. The model was later made less bulky

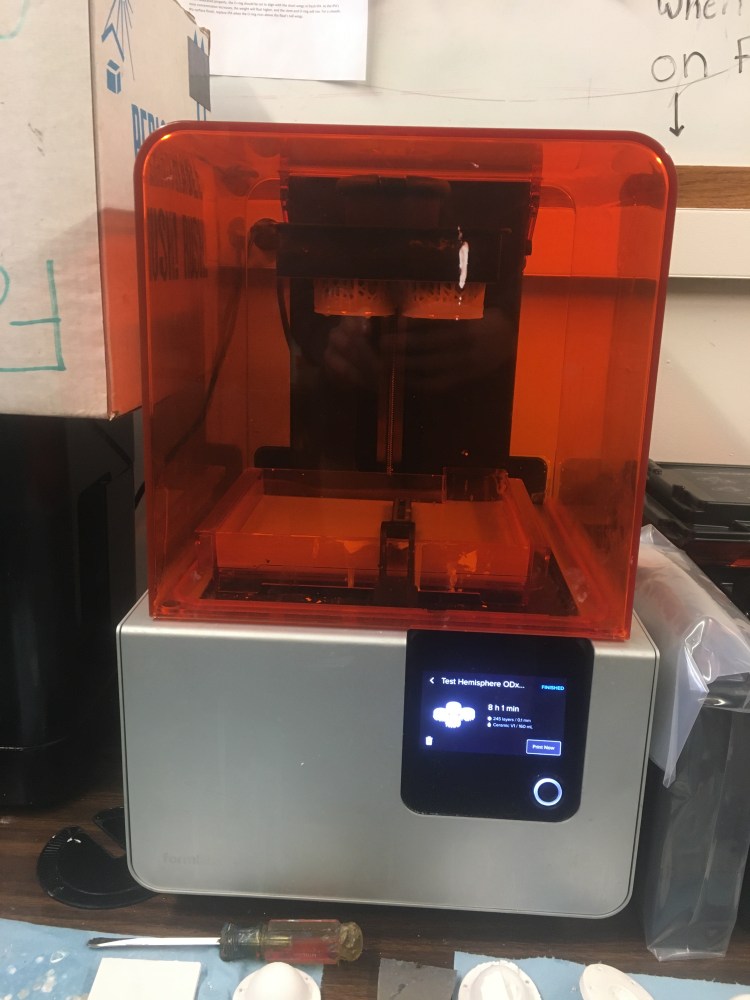

The Formlabs Form 2 printer having just completed printing a group of housings

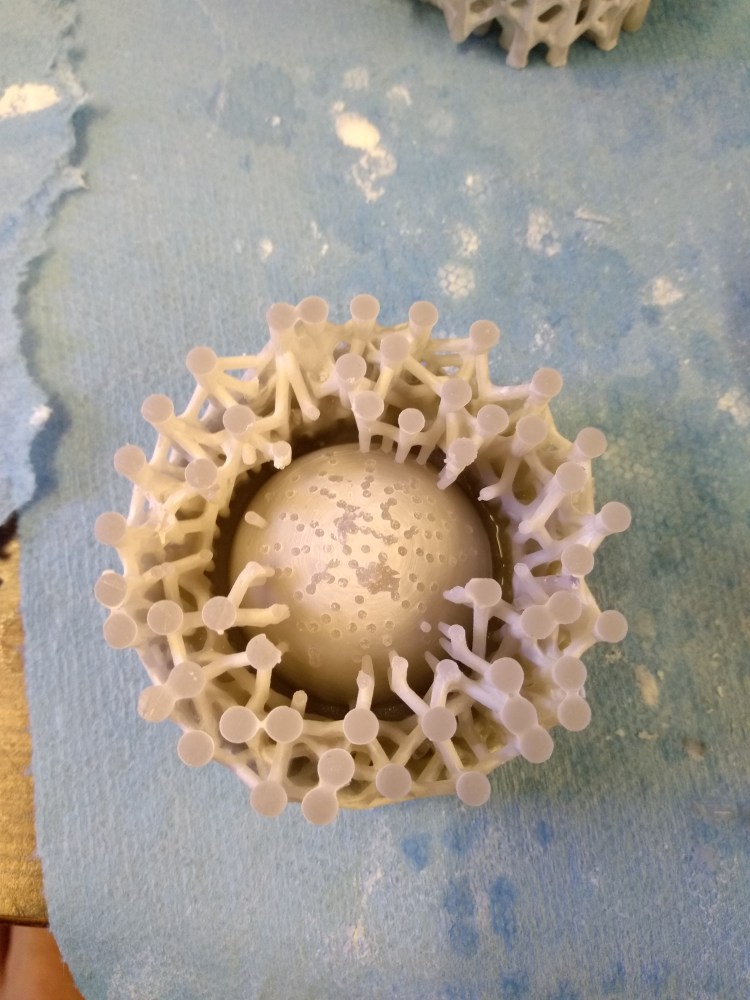

A 3D printed “green” ceramic part with the support structure still attached from printing

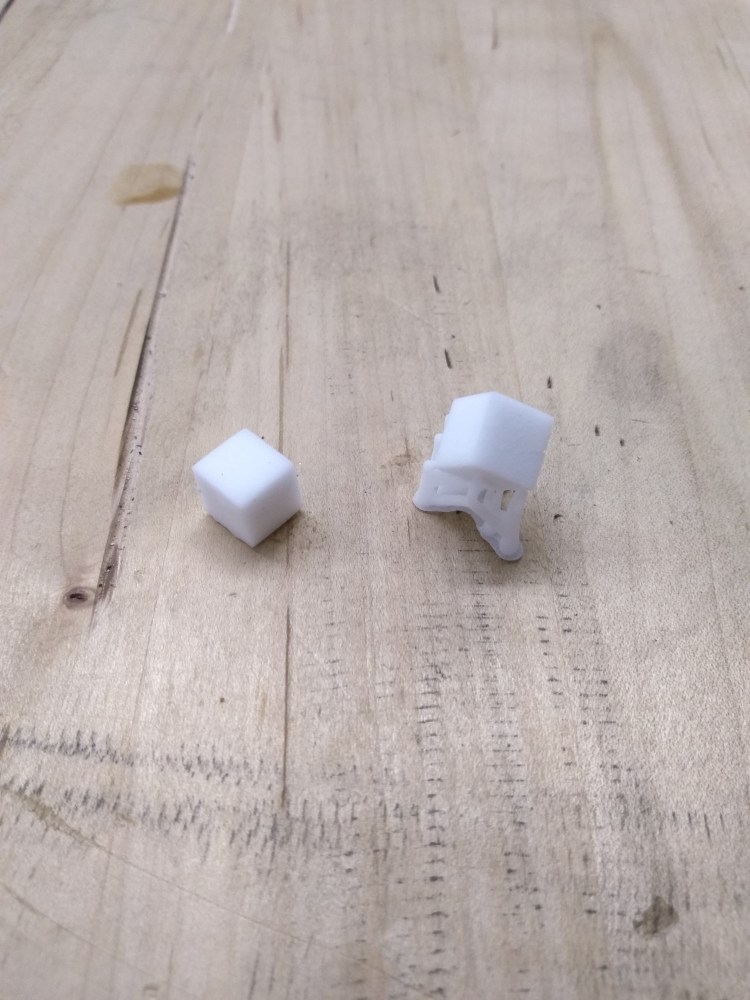

A pair of greenware hemispheres with the support material removed

The kiln mid-firing (temperature readout is in degrees centigrade, max firing temperature 1271C)

A pair of fired ceramic cubes printed on the Form 2

Four glazed ceramic hemispheres printed on the Form 2

Abstract

Ceramic is an ideal material for deep-sea pressure housings: it is lightweight and extraordinarily strong. Additive manufacturing, or 3D printing, of ceramic housings is not a novel idea. It has been attempted successfully on multiple occasions (Breddermann et al., 2016; Qi et al., 2019); however, the printers used in those studies employed selective laser sintering (SLS) technology, which is usually both costly and bulky. Stereolithography (SLA) printing provides a potential means of fabrication which would open up ceramic housings to an ease of use never before enjoyed, while also allowing for the easy design and manufacture of housings with geometries complicated beyond just spheres and cylinders. In May of 2018, Formlabs released an experimental resin for its Form 2 SLA printer, which contains silica particles suspended in a UV-cured photopolymer. This report explores the use of SLA 3D printing to produce waterproof ceramic pressure housings including methodology and workflow, models of expected performance, and laboratory results. We conclude that SLA 3D printing with ceramic resin is likely capable of rising to this challenge, and we identify what hurdles still need to be cleared to make this method a repeatable success.